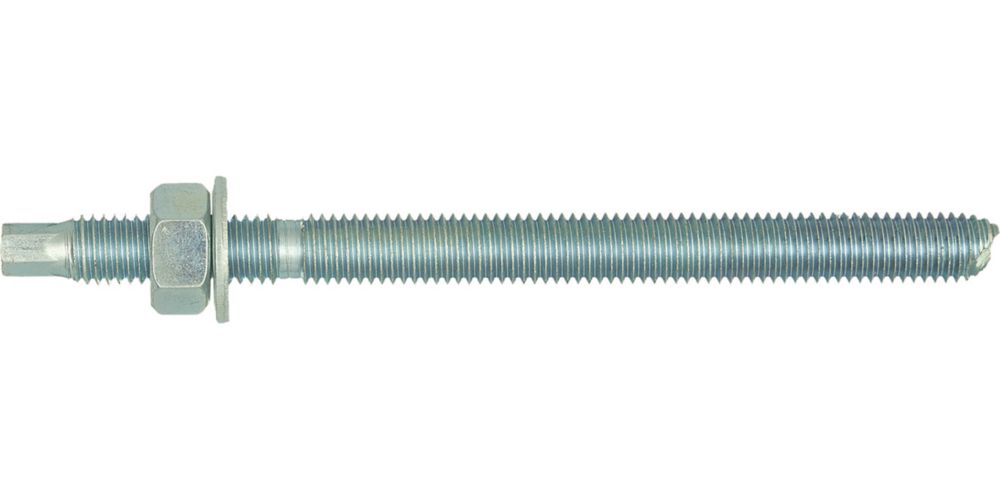

Looking for some advice. Putting up a small roofed area 4m X 4m with 8ft high RSJ. Wondering what's thes easiest way to bolt them to concrete floor. Was thinking of using thunderbolt like

mybuildingsupplies.ie

mybuildingsupplies.ie

Wondering are they strong enough or would rawl bolts/anchor bolts be better

Hex Head Thunder Bolt 12x150 - My Building Supplies | 100% Irish

Rogers of Ballymote, Co. Sligo Stock a full range of Building Supplies for the Trade and DIY customer...

Wondering are they strong enough or would rawl bolts/anchor bolts be better