Greenbeast

Member

- Location

- East Sussex

I am damn certain i have asked this before, but cannot for the life of me find it.

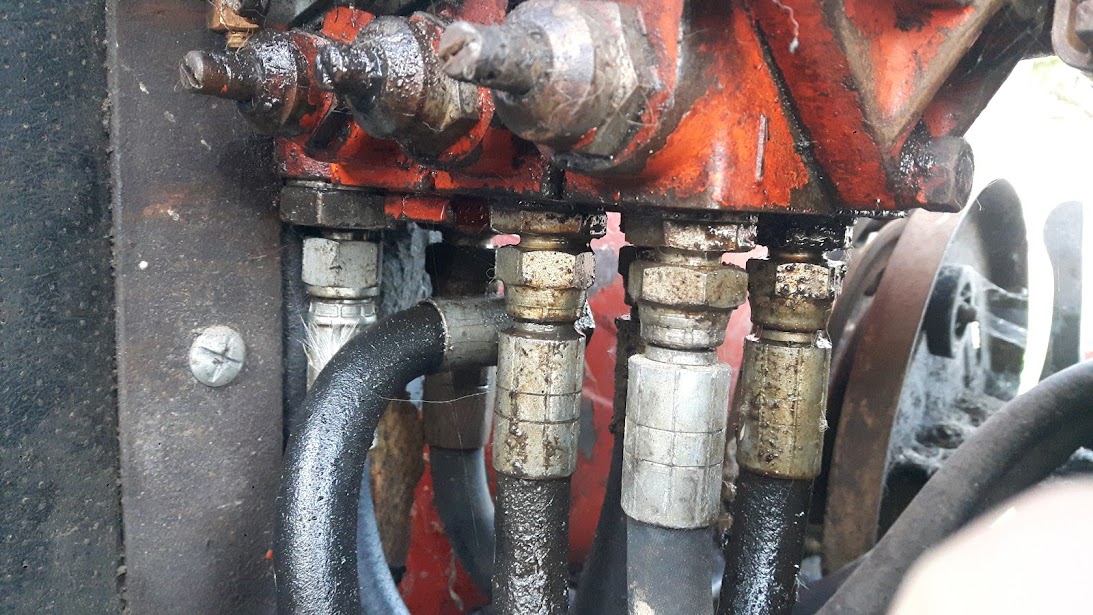

My lift arms jump a inch or so every ~5 seconds, i believe someone has told me something about a safety valve/seal letting by which causes the pump to compensate and the arms to jump.

Getting a bit irritating and might do something about fixing it but i want to try and get the correct parts in before i dismantle anything as i'm dependant on the machine

My lift arms jump a inch or so every ~5 seconds, i believe someone has told me something about a safety valve/seal letting by which causes the pump to compensate and the arms to jump.

Getting a bit irritating and might do something about fixing it but i want to try and get the correct parts in before i dismantle anything as i'm dependant on the machine