They just won’t stay done up. Jiggle about worst on old style folding rolls towed from 3PL. You can do that 14mm bolt up murder tight but comes loose, even with a spring washer. Is it due to wear in everything? The side with the assistor undoes whereas I think the opposite side gets tighter. Any thoughts @Gapples @Richard Devon @essexpete TIA

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

956xl lift arms coming off the rock shaft

- Thread starter Flat 10

- Start date

Crikey to be mentioned on the same post as Gapples and Richard D! They have proper knowledge not amateur.They just won’t stay done up. Jiggle about worst on old style folding rolls towed from 3PL. You can do that 14mm bolt up murder tight but comes loose, even with a spring washer. Is it due to wear in everything? The side with the assistor undoes whereas I think the opposite side gets tighter. Any thoughts @Gapples @Richard Devon @essexpete TIA

The 3 tractors we had in that series never suffered from that problem despite the lower links being extremely worn on one.

I would suspect wear. Could you fit some kind of tab washer? The others will know, but are there shims on there? I cannot remember.

Locktite?

Right-arm fast

Member

Maybe try using a 12.9 grade bolt with loctite as above in case the bolts are stretching ? Are you using the lower link sway blocks tightened up, just if the lower links are swaying about it might not help very much with the rocker arms sliding on the splines.

They are locked solid thanks. Not sure if I dare use loctite and 12.9 but good idea.Maybe try using a 12.9 grade bolt with loctite as above in case the bolts are stretching ? Are you using the lower link sway blocks tightened up, just if the lower links are swaying about it might not help very much with the rocker arms sliding on the splines.

averageguy54

Member

- Location

- New Brunswick, Canada

It may also be that the threads in the rock shaft are stretched. My son, who is a licensed truck mechanic ran into this problem as an apprentice, almost ended his career before it started.

He replaced the "pumpkin" or rear end gear assembly on a large tractor trailer. It proceeded to disintegrate on a 6 lane highway at rush hour. Forensic investigation revealed that the threads were so stretched from repeated rebuilding so that it was impossible to properly tighten and torque it down, letting my son off the hook.

Since the only way to repair that would be to redrill and retap the rock shaft, I'm with the loctite method and new bolts.

He replaced the "pumpkin" or rear end gear assembly on a large tractor trailer. It proceeded to disintegrate on a 6 lane highway at rush hour. Forensic investigation revealed that the threads were so stretched from repeated rebuilding so that it was impossible to properly tighten and torque it down, letting my son off the hook.

Since the only way to repair that would be to redrill and retap the rock shaft, I'm with the loctite method and new bolts.

- Location

- Down on the edge of the world

i can't really add anything to whats already been suggested.......i did check the S/M and bulletins to see if there was any special procedure or torques but nothing.

If the splines have wear on them then maybe hunt down some s/h ones out of a breakers......I don't think wear was a common issue.

I can only suggest as others have, renew the bolts (they could well be 10.9 or 12.9) and the flat washers on the ends, loctite the bolts in place and then clean up the splines - make sure they are indexed correctly and put something like Loctite 638 or high performance retaining fluid.

If the splines have wear on them then maybe hunt down some s/h ones out of a breakers......I don't think wear was a common issue.

I can only suggest as others have, renew the bolts (they could well be 10.9 or 12.9) and the flat washers on the ends, loctite the bolts in place and then clean up the splines - make sure they are indexed correctly and put something like Loctite 638 or high performance retaining fluid.

Gapples

Member

It's a tricky one as I can only echo what Richard & others have said.

I can only think it's caused by wear as this was not an issue.

Originally those arms are a dam good fit on the splines so as the arm moves up or down so does the shaft.

I suspect what's happening is you've now got movement on the arm before the shaft moves, not a lot but obviously enough to work on the washer & the bolt, tightening one side & loosening the other.

At least that's my theory for what it's worth.

A cure ? I don't know, one would of thought if the bolt & threads were completely free of oil etc using a degreaser, brake cleaner or similar then a good quality loctite would hold it ?

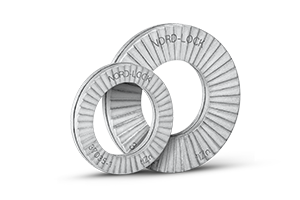

Also rather than a spring washer you could try what we called "contact" washers, such as those used by Claas an awful lot, they are those dished flat washers with ridges on them, bloody great things.

I can only think it's caused by wear as this was not an issue.

Originally those arms are a dam good fit on the splines so as the arm moves up or down so does the shaft.

I suspect what's happening is you've now got movement on the arm before the shaft moves, not a lot but obviously enough to work on the washer & the bolt, tightening one side & loosening the other.

At least that's my theory for what it's worth.

A cure ? I don't know, one would of thought if the bolt & threads were completely free of oil etc using a degreaser, brake cleaner or similar then a good quality loctite would hold it ?

Also rather than a spring washer you could try what we called "contact" washers, such as those used by Claas an awful lot, they are those dished flat washers with ridges on them, bloody great things.

I used those type of washes on my 8340 trumpet when the bolt seem to come undone.It's a tricky one as I can only echo what Richard & others have said.

I can only think it's caused by wear as this was not an issue.

Originally those arms are a dam good fit on the splines so as the arm moves up or down so does the shaft.

I suspect what's happening is you've now got movement on the arm before the shaft moves, not a lot but obviously enough to work on the washer & the bolt, tightening one side & loosening the other.

At least that's my theory for what it's worth.

A cure ? I don't know, one would of thought if the bolt & threads were completely free of oil etc using a degreaser, brake cleaner or similar then a good quality loctite would hold it ?

Also rather than a spring washer you could try what we called "contact" washers, such as those used by Claas an awful lot, they are those dished flat washers with ridges on them, bloody great things.

If there is movement on the splines would it be possible to use a loctite type product on the splines or would that break up almost immediately?

And Nordloc washers go hand in hand, in these situationsLocktite?

Gapples

Member

I used those type of washes on my 8340 trumpet when the bolt seem to come undone.

If there is movement on the splines would it be possible to use a loctite type product on the splines or would that break up almost immediately?

There may well be a product that would help on those splines, they are a hell of a load of course.

But something like that along Nord Lock washers ( contact washers ) might give it a chance.

Nord-Lock Washers

Wedge-locking security for bolted joints subjected to extreme vibration and dynamic loads.

The London Palladium event “BPR Seminar”

Dec

05

- 14,153

- 226

This is our next step following the London rally

BPR is not just a farming issue, it affects ALL business, it removes incentive to invest for growth

Join us @LondonPalladium on the 16th for beginning of UK business fight back

lwtheatres.co.uk

lwtheatres.co.uk

BPR is not just a farming issue, it affects ALL business, it removes incentive to invest for growth

Join us @LondonPalladium on the 16th for beginning of UK business fight back