- Location

- Chipping Norton

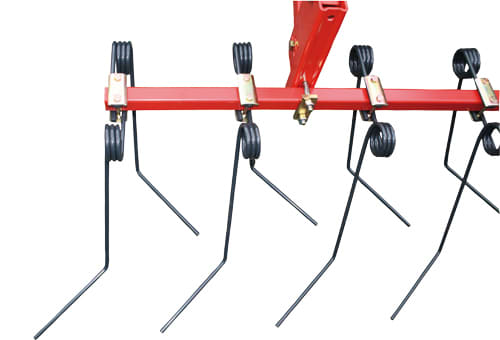

Exactly. My point is that most of the seedhawks I've seen haven't ever been re-bushed, consequently the bush has gone and the hole is now oval and the leg knackered, just for the sake of replacing a bush.The bushes are exactly why they are such a popular drill worldwide. European drills are built to be thrown away like a Chinese washing machine, the seedhawk can be rebuilt time and time again. I rebushed my 8m last autumn all with genuine parts, new bolts in all the pivots, re sealed all the rams and including labour came to £5000ish