Steevo

Member

- Location

- Gloucestershire

Edit. Based on your edit about @Fergieman. The auger is split in half and I assume one the outer "half" can be stopped whereas the inner half runs constantly.

So how do you stop it filling when full?

Edit. I see form the photos above it does have 2 seperate augers.

Edit. Based on your edit about @Fergieman. The auger is split in half and I assume one the outer "half" can be stopped whereas the inner half runs constantly.

Toaster analogy works for me, might use it in future !

If the flow of grain is too slow the grain reaches max temp quicker and burner then cuts in and out automatically as it reached max temp, if the grain moves faster then a more constant flow grain temp doesn't cause burner to trip in and out, more heat input, quicker drying time for batch, and avoids hotspots in grain, if that makes sense?

Stop putting grain in the hopper?

Downside I can see though is the filling part of the auger would be running constantly empty during drying, which would surely wear it out quicker?

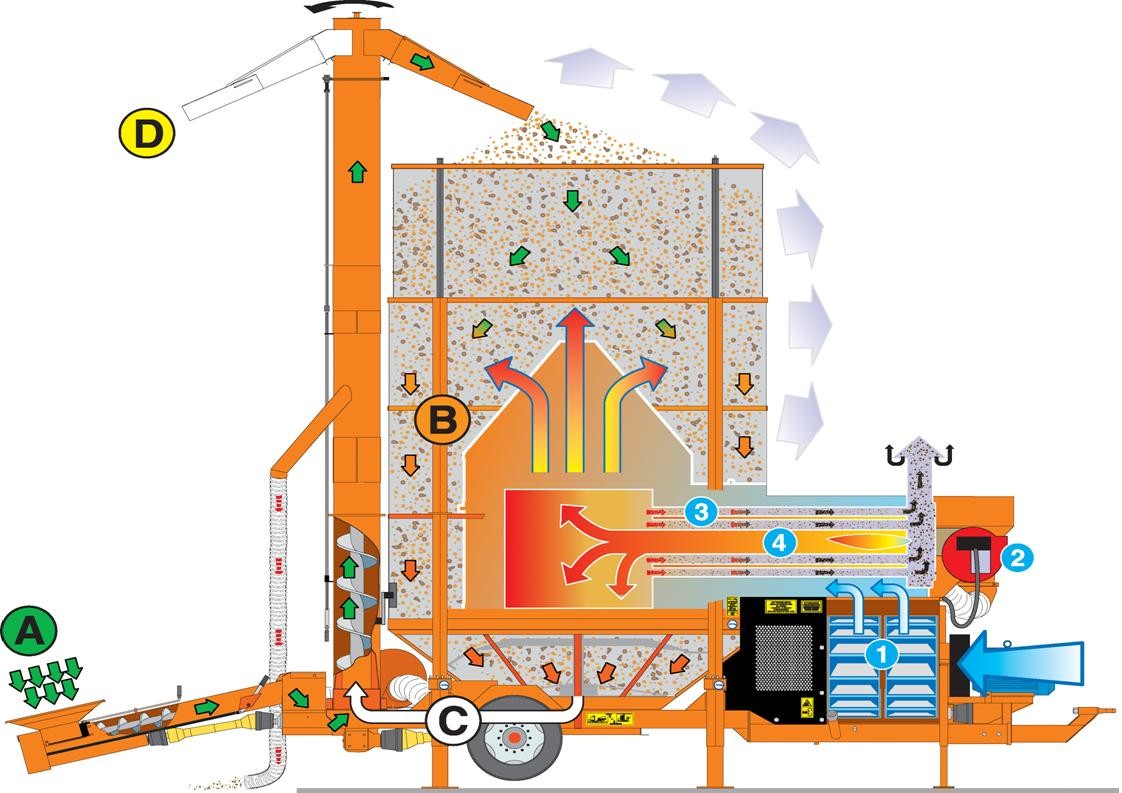

One auger running constantly with flights in opposite directions to centre or more like 1/5 intake - 4/5 recurculate (C on diagram)

Sounds like two augers to me then surely? One running from hopper to main auger, the other running from dryer tub to main auger. Neither run by same motor, or having a connected screw. But, both turn the same direction but are flighted opposite ways.

Esp from your other explanation and diagram above. On a centre auger machine the centre auger runs constantly, but the whole other auger (single length) from hopper to bottom of vertical auger is put out of gear when not filling.

Is there an extra auger to move the grain from bottom of drier to bottom of auger?

No, the loading auger on a normal drier brings grain in to the centre auger, on the Agrex the same auger has a left hand and right hand screw, the auger turns continuously, taking grain from the centre to the recirculating auger or fresh grain from the intake hopper. Other difference is when filling there is no recirculation so vertical auger is only filling and not also recirculating = faster filling.

20% is wet? try stuff at 28%.My Mecmar drier has no internal slides to adjust for wet/dry grain, it uses vari pitch augers flights to prevent blockage with very wet stuff, we never had it blocked and it's done some high 20% wheat ok, does your slide adjuster mean the agrex will dry faster (cheaper) than my current drier ?

20% is wet? try stuff at 28%.

sorry ,missed the" high" bit.I presume that's what he meant by 'high 20%'.

I'm thinking the same.I think i'll stick with my current machine, the thought of no grain recirculating while loading worries me, 28 tonne of wet wheat sat in the silo while the drier fills then opening a slide when full and asking it to start to flow, !!!! i'd rather have the wet grain constantly moving in the silo than load a couple of minutes quicker, also we start our burner as soon as the grain is over the center drying chamber, about half full, if that grain wasn't moving you can't start the burner till the drier is full, what you may gain with your adjustable flow you have lost by starting the heat latter.

Ah yes, loaded wet wheat one saturday morning & 10 minutes later ran out of gas, stopped tractor.I think i'll stick with my current machine, the thought of no grain recirculating while loading worries me, 28 tonne of wet wheat sat in the silo while the drier fills then opening a slide when full and asking it to start to flow, !!!! i'd rather have the wet grain constantly moving in the silo than load a couple of minutes quicker, also we start our burner as soon as the grain is over the center drying chamber, about half full, if that grain wasn't moving you can't start the burner till the drier is full, what you may gain with your adjustable flow you have lost by starting the heat latter.

Ah yes, loaded wet wheat one saturday morning & 10 minutes later ran out of gas, stopped tractor.

Monday morning gas arrived, started drier & nothing...opened inspection hatch & still nothing, had to poke it with a stick....9 tons of wheat to be shovelled up by hand, you only do that once.

Then there was the time a neighbours drier went on fire. Fire brigade came & put it out, soaked the grain in the pit too ( it was a bin type drier where the grain dosen't move ) he brought the grain round for me to dry, it was full of black, fist sized burnt lumps & was off the scale in moisture, the insurance paid for the grain so it was only costing the drying.

Put it in the drier & the place turned black, put it on & went to bed, early next morning it was down to 28%

So yes there is an extra auger after all. Mecmar, Master, Opico etc have 2 augers, one central and one loading auger which as say does take the grain to the centre of the machine.

Sorry fergieman, hope you didn't hit your head to hard against the wall! Slight misunderstanding on my part but hopefully all clear now?

I think i'll stick with my current machine, the thought of no grain recirculating while loading worries me, 28 tonne of wet wheat sat in the silo while the drier fills then opening a slide when full and asking it to start to flow, !!!! i'd rather have the wet grain constantly moving in the silo than load a couple of minutes quicker, also we start our burner as soon as the grain is over the center drying chamber, about half full, if that grain wasn't moving you can't start the burner till the drier is full, what you may gain with your adjustable flow you have lost by starting the heat latter.

You can recirculate if you wish, operator can choose but there is a full width stirrer across the bottom of the bin as well.

What do you have for support/service/maintenance/break downs?