Good luck I have done one or two I just ground them like a normal twist drill but I ended up putting to much heat in the doing it so it don’t work very wellAny tips on sharpening De Walt extreme double fluted bits with a standard grinding wheel ?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Decent quality drill bits

- Thread starter Boomerang

- Start date

I'll second that! I've made similar drill bits for drilling and countersinking in one go, let's say it's a head scratcher! The tricky bit is keeping the sides of the 'pilot' straight whilst grinding the relief on the step.

You'll want a well dressed grinding wheel, a tub of water to keep dipping the bit in to stop it heating up, and the patience of a saint!

You'll want a well dressed grinding wheel, a tub of water to keep dipping the bit in to stop it heating up, and the patience of a saint!

its a game plan that works quite well i agree altho if your trying to remove a stud thats buried with a lot of surrounding land then its less effective altho anything is a help.+1, if they're seized then weld a nut on to the stud and pour cold water over it. I've yet to find a stud that wouldn't come out with this method.

ive been trying the acetone and ATf mix to see if what they are saying is credible in my world, ive refilled it a few times to my surprise, the acetone wicks in quicker (for what it can) than the likes of wd, it draws in some oil for lube with it, only downside is it separates but a quick shake gets it back in order.

Any tips on sharpening De Walt extreme double fluted bits with a standard grinding wheel ?

i was waiting for that question to come up.

i have a few of them here and altho a good drill i keep em mostly for the mill and lathe.

the pattern is a grand idea but sharpening them is the one downside to them imo, id imagine when it comes to the first or second sharp for most its lookin more like a std drill than what it once was.

to sharpen it as it originally was id be a challenge for anyone not used to sharpening drills.

it is possible to do it tho but you need a well dressed, well cornered wheel.

my man tom here is a smart cookie, this video would help you practice and learn if you were interested.

or you could just buy a drill sharpener, and im not talking about a drill doctor there either, i personally dont rate them but i understand why a lot do.

CORK

Member

- Location

- East Cork, Ireland

its a game plan that works quite well i agree altho if your trying to remove a stud thats buried with a lot of surrounding land then its less effective altho anything is a help.

ive been trying the acetone and ATf mix to see if what they are saying is credible in my world, ive refilled it a few times to my surprise, the acetone wicks in quicker (for what it can) than the likes of wd, it draws in some oil for lube with it, only downside is it separates but a quick shake gets it back in order.

i was waiting for that question to come up.

i have a few of them here and altho a good drill i keep em mostly for the mill and lathe.

the pattern is a grand idea but sharpening them is the one downside to them imo, id imagine when it comes to the first or second sharp for most its lookin more like a std drill than what it once was.

to sharpen it as it originally was id be a challenge for anyone not used to sharpening drills.

it is possible to do it tho but you need a well dressed, well cornered wheel.

my man tom here is a smart cookie, this video would help you practice and learn if you were interested.

or you could just buy a drill sharpener, and im not talking about a drill doctor there either, i personally dont rate them but i understand why a lot do.

@tinman Well D, after watching this video I picked up a bench grinder this morning. Nothing special, a 6” Jefferson for under €100. Should be fine for drill bits and the like I’d say. 2850 rpm. I have some old but good quality bits which I’m sure could be rejuvenated with a new edge. Some must be 60+ years old and belonged to an ancestor who was into lathes and the like.

start with the bigger bits they are much easier to see the right angles on,I have a 60 degree angle marked on the tool rest on my grinder, takes out the guess work@tinman Well D, after watching this video I picked up a bench grinder this morning. Nothing special, a 6” Jefferson for under €100. Should be fine for drill bits and the like I’d say. 2850 rpm. I have some old but good quality bits which I’m sure could be rejuvenated with a new edge. Some must be 60+ years old and belonged to an ancestor who was into lathes and the like.

alright J.@tinman Well D, after watching this video I picked up a bench grinder this morning. Nothing special, a 6” Jefferson for under €100. Should be fine for drill bits and the like I’d say. 2850 rpm. I have some old but good quality bits which I’m sure could be rejuvenated with a new edge. Some must be 60+ years old and belonged to an ancestor who was into lathes and the like.

rough em out with the coarse wheel if you really have to and finish with the fine one.

its a trial and error game, had a lecturer at a college who could put a damn fine edge on a bit by the eye and when gauged up was pretty damn close in fairness, i asked him how long he was sharpening drills for and he said over 30 years and he was still learning how to do it right....

you could get yourself a drill gauge, quality ones on the bay are sharp but less would do.

or the two nuts together trick is fiddly but acurate enough.

maybe get jiggy with the grinder table and fashion up cork version, what with a guide that ill slide on the edge of it to keep you on the angle, there be videos of such contraptions.

or there's the controversial drill bit sharpener add-on if you want to cheat a bit.

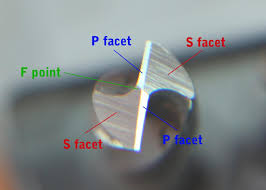

either way in no time at all you'll be dishing out the likes of this beauty...

CORK

Member

- Location

- East Cork, Ireland

alright J.

rough em out with the coarse wheel if you really have to and finish with the fine one.

its a trial and error game, had a lecturer at a college who could put a damn fine edge on a bit by the eye and when gauged up was pretty damn close in fairness, i asked him how long he was sharpening drills for and he said over 30 years and he was still learning how to do it right....

you could get yourself a drill gauge, quality ones on the bay are sharp but less would do.

or the two nuts together trick is fiddly but acurate enough.

maybe get jiggy with the grinder table and fashion up cork version, what with a guide that ill slide on the edge of it to keep you on the angle, there be videos of such contraptions.

or there's the controversial drill bit sharpener add-on if you want to cheat a bit.

either way in no time at all you'll be dishing out the likes of this beauty...

Top man D, thanks. The Oxford is ticking like a mouses heart - thanks for that one too.

Wheatseeker

Member

What exactly will a cobalt drill make a hole through then, and will it do it repeatedly? Never bought any.

As said above cobalt bits are excellent and they will drill stainless steel for example. Real cobalt bits are always a dull gold colour and not a shiny gold. They are either 5% or 8% cobalt and the price would reflect this.

Turnip_Head

Member

- Location

- UK

Hi chaps,

If ANYONE needs decent twist drill FREE samples, contact https://heygotools.com/contact-heygo/

Cheers

If ANYONE needs decent twist drill FREE samples, contact https://heygotools.com/contact-heygo/

Cheers

Last edited:

Grassman

Member

- Location

- Derbyshire

They are in China?Hi chaps,

If ANYONE needs decent twist drill FREE samples, contact https://heygotools.com/contact-heygo/

Cheers

Turnip_Head

Member

- Location

- UK

Good China firm, are we boycotting China?

Turnip_Head

Member

- Location

- UK

Much shortage of cobalt due to modern car batteries.

May Event: The most profitable farm diversification strategy 2024 - Mobile Data Centres

Apr

02

- 1,799

- 32

With just a internet connection and a plug socket you too can join over 70 farms currently earning up to £1.27 ppkw ~ 201% ROI

Register Here: https://www.eventbrite.com/e/the-mo...2024-mobile-data-centres-tickets-871045770347

Tuesday, May 21 · 10am - 2pm GMT+1

Location: Village Hotel Bury, Rochdale Road, Bury, BL9 7BQ

The Farming Forum has teamed up with the award winning hardware manufacturer Easy Compute to bring you an educational talk about how AI and blockchain technology is helping farmers to diversify their land.

Over the past 7 years, Easy Compute have been working with farmers, agricultural businesses, and renewable energy farms all across the UK to help turn leftover space into mini data centres. With...

Register Here: https://www.eventbrite.com/e/the-mo...2024-mobile-data-centres-tickets-871045770347

Tuesday, May 21 · 10am - 2pm GMT+1

Location: Village Hotel Bury, Rochdale Road, Bury, BL9 7BQ

The Farming Forum has teamed up with the award winning hardware manufacturer Easy Compute to bring you an educational talk about how AI and blockchain technology is helping farmers to diversify their land.

Over the past 7 years, Easy Compute have been working with farmers, agricultural businesses, and renewable energy farms all across the UK to help turn leftover space into mini data centres. With...