Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How can I mend this?

- Thread starter . Q

- Start date

TripleSix

Member

- Location

- Helmsley, North Yorkshire

What engine is it off?

Just get in there with the grinder and the mig, nowt to lose?

Just get in there with the grinder and the mig, nowt to lose?

Grind it back until your confident your gonna penetrate all the way through, ideally clamp the whole head solid on a flat work bench, weld it up with plenty of weld and leave it clamped up until it’s cool... then spend many man hours grinding it up tidy ... then take it too a machine shop too be skimmed as all that heat might have distorted the head slightly... then get the valves seated properly and bolt it back together.... pretty much any well equipped machine/fab shop will do it for you it’s just how much ££££ you want too spend

Deutzdx3

Member

As above with the addition, pre heat the head being it’s cast iron. If it were mine I would be looking online to see what the most suitable wire mix would be. Even possibly mig brazing it if you have that facility. Post warm it as well to all the whole thing to cool evenly. Will reduce chance of cracking. Then as mentioned skim it just incase. [emoji106]

A1an

Member

If you do weld it make sure you cool it as slow as possible or it will crack.

I once had the local blacksmith weld a cast iron manifold for me. He heated the manifold up to cherry red and whilst welding there was a lad still heating the rest of the manifold, he then buried it deep in a box of lime where it stayed for 24hrs.

I once had the local blacksmith weld a cast iron manifold for me. He heated the manifold up to cherry red and whilst welding there was a lad still heating the rest of the manifold, he then buried it deep in a box of lime where it stayed for 24hrs.

deleted user 837354

Member

If you do weld it make sure you cool it as slow as possible or it will crack.

I once had the local blacksmith weld a cast iron manifold for me. He heated the manifold up to cherry red and whilst welding there was a lad still heating the rest of the manifold, he then buried it deep in a box of lime where it stayed for 24hrs.

Seen a chap done similar. Has to be heated up nice although someone once said to me they had done an engine part using a gas barbecue on full bore with the lid closed.

- Location

- Ardrossan Ayrshire

TripleSix

Member

- Location

- Helmsley, North Yorkshire

£340 for a new head

kubota 1403 new D1403 Kubota New Cylinder Head for L2600F L2600D | eBay

Find many great new & used options and get the best deals for kubota 1403 new D1403 Kubota New Cylinder Head for L2600F L2600D at the best online prices at eBay! Free delivery for many products.

rover.ebay.com

Jameshenry

Member

- Location

- Cornwall

I wouldn't even attempt it, there will be a replacement head out there somewhere, only way to go

There's a thing called the dunning cruger effect and its cumming into play here.

If you do repair that head {which sounds crazy given a new one could be bought for 300 odd quid} you make sure you give it to someone who is competent at the job, it's a one trick pony and not something you lash into with a mig welder.

There is a world of things to be aware of when dealing with cast iron and a lot of experience required.

Anyways, maybe try JEM engines up near Falkirk, last time I was there there wasn't much he didn't have for kubots engines on the shelf, ask for Erik.

If you do repair that head {which sounds crazy given a new one could be bought for 300 odd quid} you make sure you give it to someone who is competent at the job, it's a one trick pony and not something you lash into with a mig welder.

There is a world of things to be aware of when dealing with cast iron and a lot of experience required.

Anyways, maybe try JEM engines up near Falkirk, last time I was there there wasn't much he didn't have for kubots engines on the shelf, ask for Erik.

Brilliant, thank you all for your help.

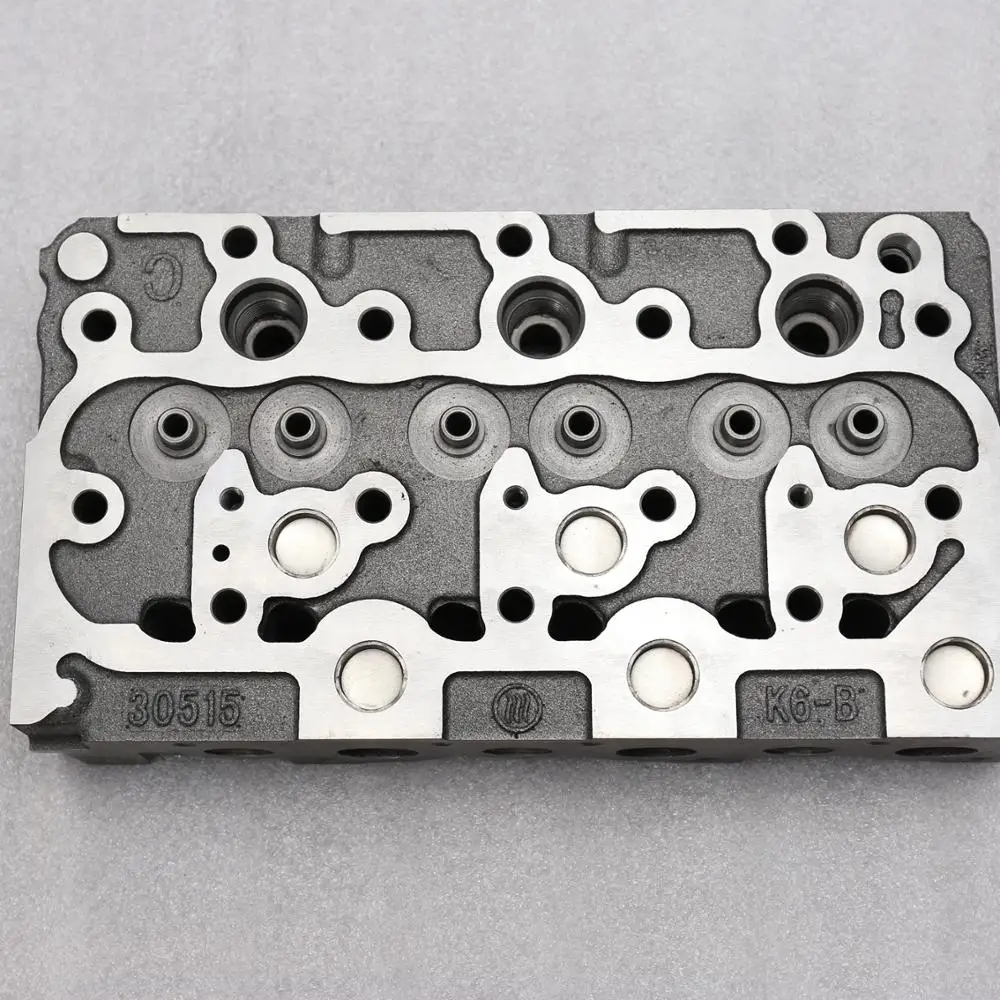

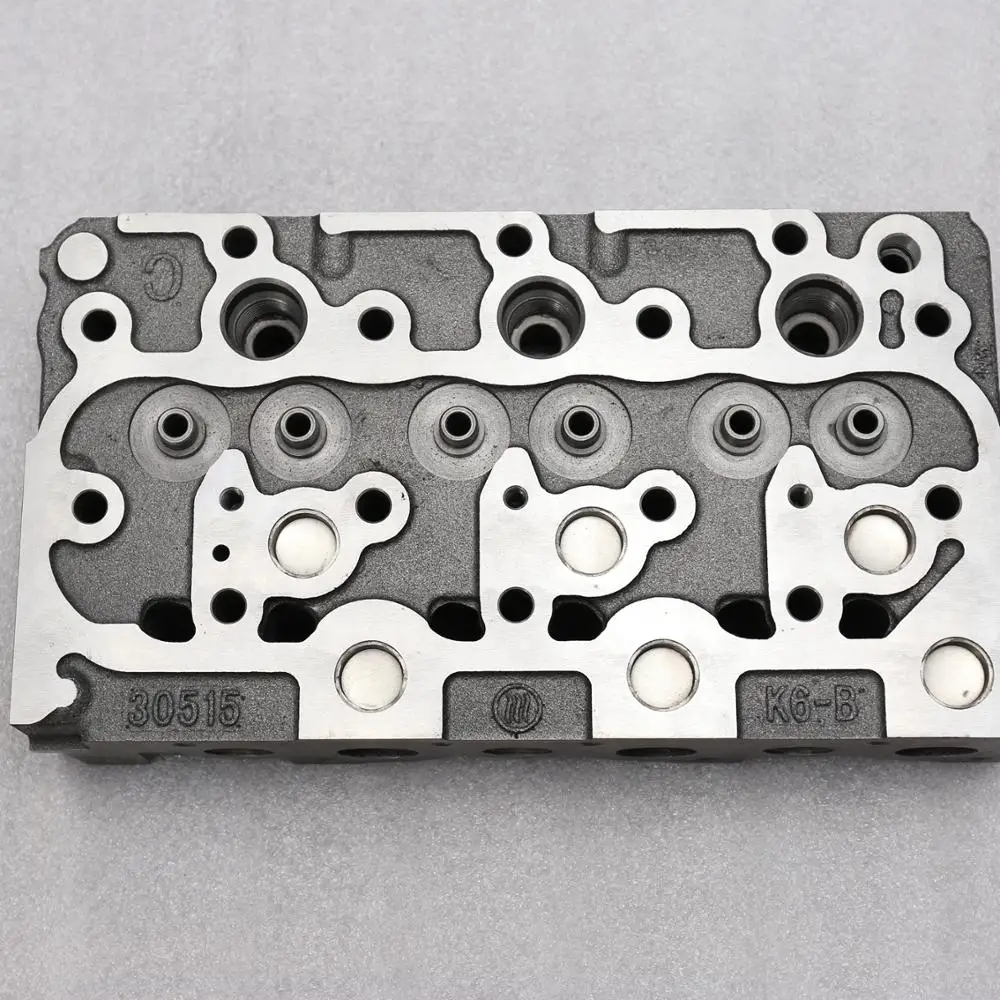

It is a Kubota D1402, looks like parts are available;

https://www.ebay.co.uk/itm/KUBOTA-D...771604?hash=item3f85070d94:g:eX4AAOSwYzFZmw4W

This forum is great for subjects like this, everyone's an expert at something ..I just never thought to look on the pump for engine No.

Are you sure I can`t try JB weld ??

It is a Kubota D1402, looks like parts are available;

https://www.ebay.co.uk/itm/KUBOTA-D...771604?hash=item3f85070d94:g:eX4AAOSwYzFZmw4W

This forum is great for subjects like this, everyone's an expert at something ..I just never thought to look on the pump for engine No.

Are you sure I can`t try JB weld ??

A1an

Member

You get a "1 year out" t shirt.I'd say it's a Kubota D1403 engine. Engine serial number should be on the top of the inj pump housing,just above the pump inspection cover (in your first picture).

- Location

- Scottish Highlands

Here's one for $100. Probably direct from the manufacturer!

www.alibaba.com

www.alibaba.com

Kubota D1402 Cylinder Head - Buy Kubota D1402 Cylinder Head,Kubota D1402 Cylinder Head Factory,Kubota D1402 Cylinder Head Product on Alibaba.com

Kubota D1402 Cylinder Head - Buy Kubota D1402 Cylinder Head,Kubota D1402 Cylinder Head Factory,Kubota D1402 Cylinder Head Product on Alibaba.com

- Tags

- kubota

The London Palladium event “BPR Seminar”

Dec

05

- 15,384

- 235

This is our next step following the London rally

BPR is not just a farming issue, it affects ALL business, it removes incentive to invest for growth

Join us @LondonPalladium on the 16th for beginning of UK business fight back

lwtheatres.co.uk

lwtheatres.co.uk

BPR is not just a farming issue, it affects ALL business, it removes incentive to invest for growth

Join us @LondonPalladium on the 16th for beginning of UK business fight back