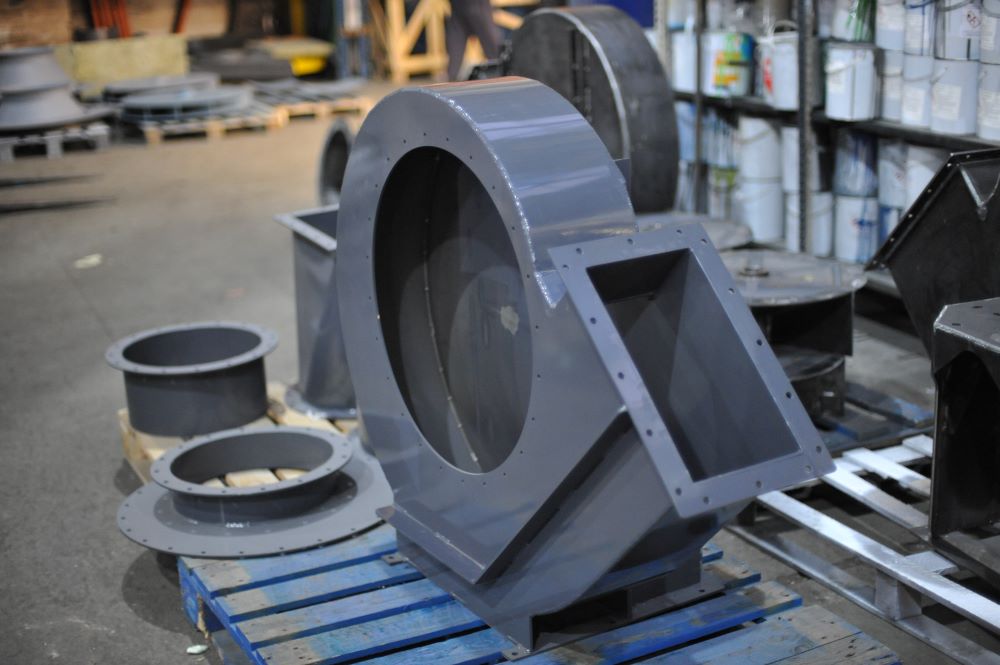

Just refettling an 11kW fan for a grain drier. The fan is about 3 ft diameter and because it's been left outside, the assembly must be rebalanced, so was wondering if anyone had any ideas for doing it.

At the moment I was just going to turn it gently by hand and after seeing where it stopped, adding small weights to try to balance it again. This seems on consideration to be possibly a very long winded process, so can anyone help with suggestions to speed the whole process up, and possibly make it more scientific?

Cheers in advance for your ideas.

At the moment I was just going to turn it gently by hand and after seeing where it stopped, adding small weights to try to balance it again. This seems on consideration to be possibly a very long winded process, so can anyone help with suggestions to speed the whole process up, and possibly make it more scientific?

Cheers in advance for your ideas.