darrenjlobb

Member

- Location

- Cornwall

Afternoon...

Looking to try and improve the seperation in barley on a T560 machine... Have already jacked up rear axle, fitted several walker fishbacks / extensions and auger speed flights... but feel the combine has alot more potential capacity in tough / heavy straw conditions if setup in a more suitable manor.

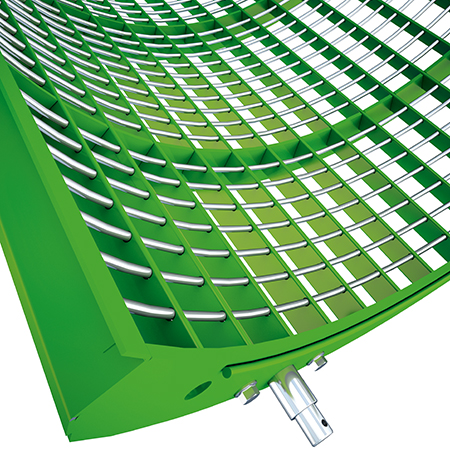

Have read in a few places the later MY T's had a modified rear separator concave in them with an openable door part way round? Does anyone on here have a machine with this fitted / any more info? or even better, any pictures of this?

Have been debating removing a row or two from middle / rear of my rear concave, has anyone tried this ? Only cutting Barley and Wheat, with extremely high straw volumes!!

Losses are just about always going over in the straw, so feel theres room for more capacity if it had more chance to get down onto the chaffer.

Anyone have any thoughts / info?

Cheers

Looking to try and improve the seperation in barley on a T560 machine... Have already jacked up rear axle, fitted several walker fishbacks / extensions and auger speed flights... but feel the combine has alot more potential capacity in tough / heavy straw conditions if setup in a more suitable manor.

Have read in a few places the later MY T's had a modified rear separator concave in them with an openable door part way round? Does anyone on here have a machine with this fitted / any more info? or even better, any pictures of this?

Have been debating removing a row or two from middle / rear of my rear concave, has anyone tried this ? Only cutting Barley and Wheat, with extremely high straw volumes!!

Losses are just about always going over in the straw, so feel theres room for more capacity if it had more chance to get down onto the chaffer.

Anyone have any thoughts / info?

Cheers